Overview

In the current business climate organizations and customers have come to expect a great deal of information about the products they are buying. Call this the “Amazon Effect” or whatever you like, but we have all come to expect a great deal of information not only about what we are buying but also about its availability, when it is being shipped, and when it will arrive. As a manufacturing organization, especially in environments where you are selling directly to customers or where you have to “build to order”, meeting your commitments to customers especially on product delivery and timing becomes very important. A quick Internet search using the terms “Causes of Customer Dissatisfaction” will turn up issues such as “not keeping your commitments” or “slow delivery” or “inability to make commitments” or “lack of product availability information” will often turn up as some of the top ten reasons for customer dissatisfaction.

Flipping this issue on its head, how can an organization, in particular a manufacturing organization that builds to order and doesn’t sell through external parties actually satisfy its customers? What if the organization could actually make product timing commitments? Then meet those commitments? Provide clear insight as to product availability? Communicate when there are problems? Studies have demonstrated that failing to meet delivery commitments is one of the top reasons why organizations will switch vendors. So what are some best practices organizations could employ to manage On-Time Delivery and expectations?

We will discuss five Best Practices in how companies can use their Enterprise Resource Planning System (ERP), with an Analytics capability and Business Intelligence tools to better manage On-Time Delivery for their customers. Those Best Practices include:

- Managing and Setting the Initial Due Date with the Customer

- Understanding and Tracking the Customer’s Request Date

- Communicate with the Customer Regularly on the Status of the Ship Date

- Track Performance against the Original Due Date, Understand Variances

- Track Performance against the Request Date, Understand Variances

Best Practices

Managing and Setting the Initial Due Date with the Customer

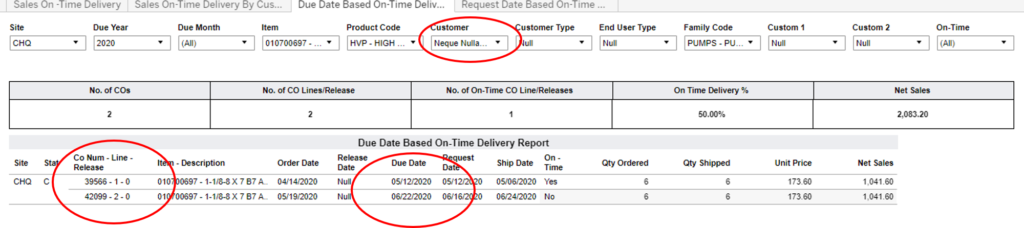

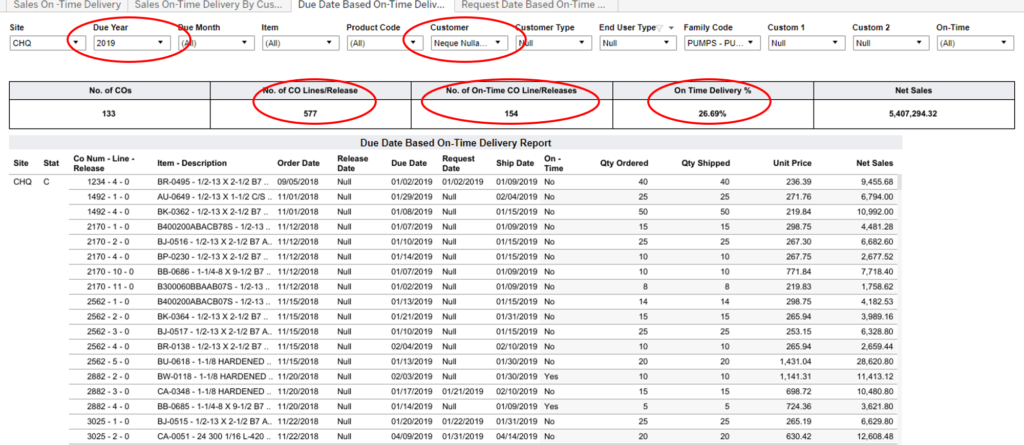

The importance of setting the right expectations with the Customer in regards to product availability and timing cannot be overemphasized. In many organizations the salesperson communicates directly with a customer service person and they can inform as to product availability. This information could be the result of the “tribal knowledge” of the customer service person, or if the organization has implemented a Advanced Planning & Scheduling (APS) capability in their ERP system, then the APS functionality can inform of an appropriate Due Date. This Due Date needs to be tracked and communicated back to the Customer. In Figure 1 below is an example of the Due Date that is tied to a particular Customer Order Line Number. (see red ellipses highlighting Customer Name, Customer Order Line Number, and Due Date). This information is available via a “Due Date Based On-Time Delivery Report”.

This Due Date should not be changed. It is the date that the organization and the Customer have agreed to as to when the Customer needs the product and when the organization can actually provide that product. It becomes the de facto “On-Time Delivery” date. Changing this Due Date is the equivalent of “moving the goalposts” in a sporting event. It undermines an organization’s credibility and causes Customers to lose faith in an organization and ultimately take their business somewhere else.

Understanding and Tracking the Customer’s Request Date

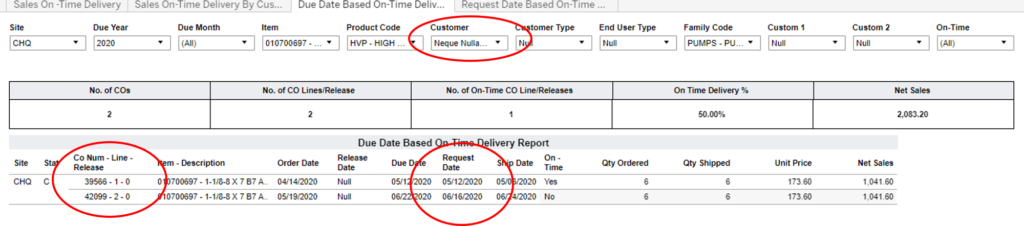

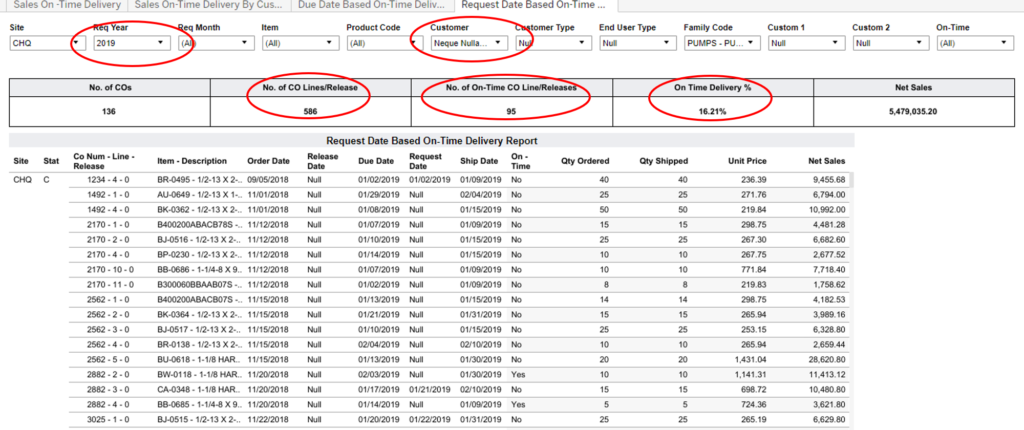

As a best practice in business it is also important to understand the Customer’s Request Date. This date may or may not be the same as the Due Date but the value of it is important in both the short term operation of the business and for the long term planning of the organization’s resources and investments. Below in Figure 2 you can see an example of this date (see red ellipses highlighting Customer Name, Customer Order Line Number, and Request Date)

Again as a Best Practice this date should not be changed. The management of the organization can use this to understand a number of aspects of their business operations. In the near term, this illustrates the customer’s expectations for the company’s products. If the dates expected are within 7 days or less, this indicates the customer believes this is a common off the shelf item. If the Request Date is a little further out such as 7 to 30 days this would indicate the customer’s expectations are that some customization of the product might be expected. If the Request Dates are farther than 30 days and beyond, this would indicate that the customer believes this is a customized and perhaps custom product that is not readily available and would need to be produced just for them.

In the long term, if the Request Date is much closer in time than the Due Date and this is a commonly occurring phenomenon, then this can be an indication of a mismatch between the Customer’s expectations and what the organization is able to deliver. It may be a sign that the company needs to make additional investments in production capacity or perhaps change to a build to stock model versus a build to order model.

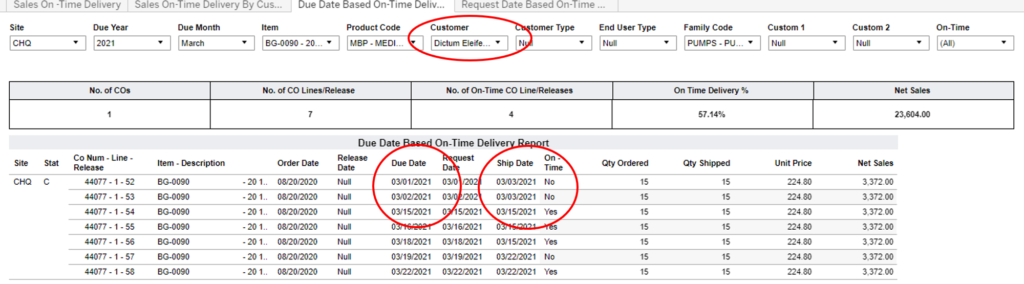

Communicate with the Customer regularly on the Status of the Ship Date

One thing that the “Amazon Effect” has done is to raise the expectations of everyone, not only in our personal lives but also in our professional lives, as to the level of information and communication, we expect to be provided from whatever vendor or provider of goods and services that we deal with. It is critical for organizations to know internally what they can deliver and also to communicate that to the Customer. Below in Figure 3 is a report that looks at the Due Date and the Ship Date and whether the Ship Date was in time to meet the Due Date. (In Figures 3 below for the Customer Dictum Eleifend we see for the first Line Item the Due Date Date was 03/01/2021 and the Ship Date was 03/03/2021 thus in the column labeled On Time we see the result is No which means the Due Date was missed. In the 3rd Line Item we see Due Date Date was 03/15/2021 and the Ship Date was 03/15/2021 thus in the column labeled On Time we see the result is Yes which means the Due Date will be met.). Such a report could also be sent via email to a Customer and thus it would communicate to the Customer upcoming and past product Ship Dates. (NOTE: In the example below this data is for a future period, but such a report can also be generated to reflect any time period, past or present.)

Track Performance against the Original Due Date, Understand Variances

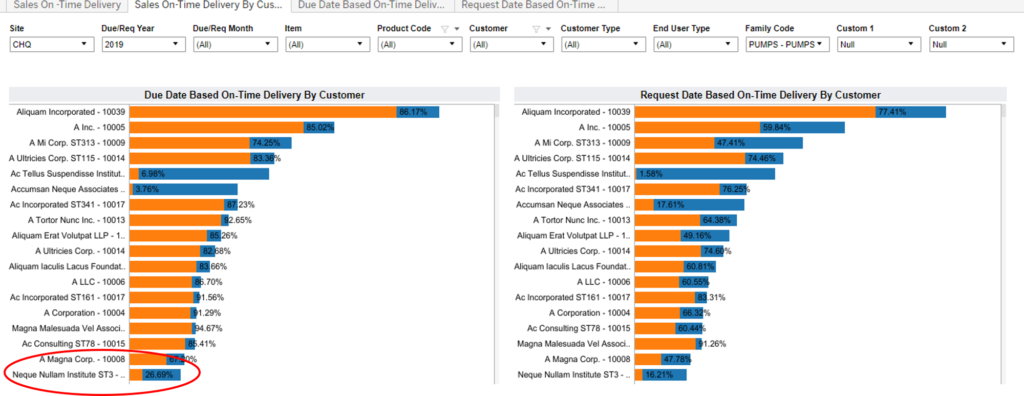

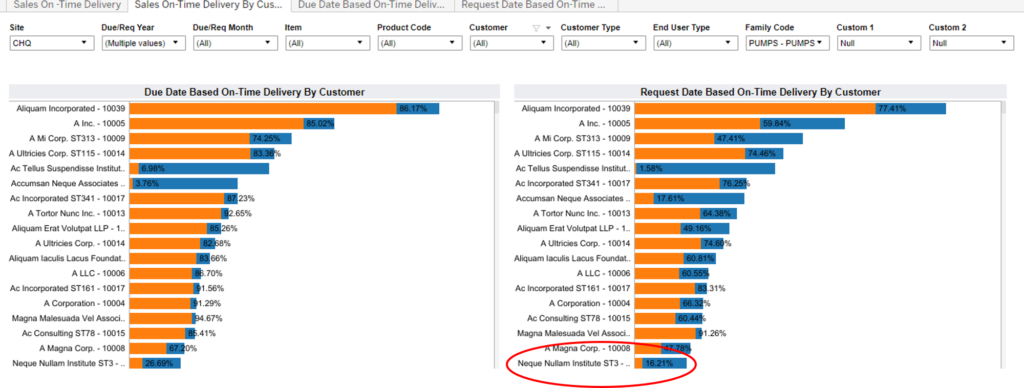

For an organization to be effective, it needs to know how well it is performing against its Key Performance Indicators (KPIs). KPIs are worthless if not used to effectively and measured and managed. Years ago I got into a debate with an executive about how to measure the organization’s performance. His contention was that if you don’t measure it you can’t manage it. I argued while this is true, it is only part of the story. Before you can measure it, you have to capture it, then you can measure it, and ultimately manage it. This is true about the Due Date. It should be captured initially when the order is placed. This is the organization’s best initial estimate as to when it can actually deliver on the order. On-Time Delivery then is when the organization either hits or delivers sooner than the Due Date. Think of the Due Date as the On-Time Delivery metric for the organization. It is the KPI for the organization to know how well it is delivering on its promises. If this Due Date is missed then On-Time Delivery is not really On-time Delivery but Late-Time Delivery. Below in Figure 4 we see a report that shows On Time Delivery performance in 2019 by Customer. Looking at the bottom of the report we see a Customer “Neque Nullam Institute” where our On-Time Delivery performance was only 26%. If we click on this particular bar in the chart the system allows us to drill into this data and see the detail as in Figure 5 (see below). Here we see detail on the Date, Customer, Number of Customer Order Lines, Number that were On-Time and the On-Time percentage. The details of specific Customer Orders are then shown below in a tabular format.

Track Performance against the Request Date, Understand Variances

Similar to the analysis above for Due Date, it is valuable to understand how the organization is able to perform against the Request Date. In this case the Request Date is when the Customer originally requested to receive the Order as opposed to the Due Date which is the joint agreement between the Customer and the organization as to when it could be Delivered. Below in Figure 6 we see a similar view as what we saw in Figure 4, but now we are looking at the Request Date portion of this same image. Here we see that for the Customer “Neque Nullam Institute” the Request Date based On-Time performance is only 16%. If we click on this particular bar in the chart the system allows us to drill into this data and see the detail as in Figure 7 (see below). Here we see detail on the Date, Customer, Number of Customer Order Lines, Number that were On-Time and the On-Time percentage. The details of specific Customer Orders are then shown below in a tabular format.

Summary

We have examined some of the different metrics that can be used to manage an organization’s performance against the commitments it makes to its Customers. We looked at this with an understanding that the level of expectations that most Customers have has risen over time based on marketplace changes in both the business and the consumer world. Key to these expectations is a phenomenon sometimes called the “Amazon Effect”, whereby rapid delivery and ongoing status communication of orders and order delivery have become the norm. We looked at five different metrics that organizations can use to not only measure their own performance but also communicate to their Customers. Those metrics include:

- Managing and Setting the Initial Due Date with the Customer – An agreement between the organization and the Customer as to when a product can be delivered

- Understanding and Tracking the Customer’s Request Date – The Customer’s actual original date when they want the product to be delivered.

- Communicate with the Customer regularly on the Status of the Ship Date – Keeping the Customer informed as to when the product will actually ship.

- Track Performance against the Original Due Date, document reasons for late orders – Keeping the Due Date constant and measuring by Customer, Customer Order Number, and Item how well the organization performed against this date. This requires a detail capability to look at this Due Date down to the Customer Order Number detail

- Track Performance against the Request Date, analyze and implement changes – Keeping the Request Date constant and measuring by Customer, Customer Order Number, and Item how well the organization performed against this date. This requires a detail capability to look at this Request Date down to the Customer Order Number detail

A key component in managing this is not only the ability to report against these On-Time Delivery metrics, but also the underlying business processes that ensure integrity in what is being recorded and reported. If the dates such as Due Date and Request Date can be moved and altered by anyone in the organization then the integrity of the process is destroyed and Customers will quickly lose faith in the organization’s promises and commitments.

At IntelliDash we provide a series of dashboards and reports that can enable an organization to implement a “Best Practice” in managing and communicating On-Time Delivery metrics and KPIs to their Customer. Some examples of these dashboards and reports have been included in this article. Reach out to us and we will be happy to illustrate how it could work in your environment.